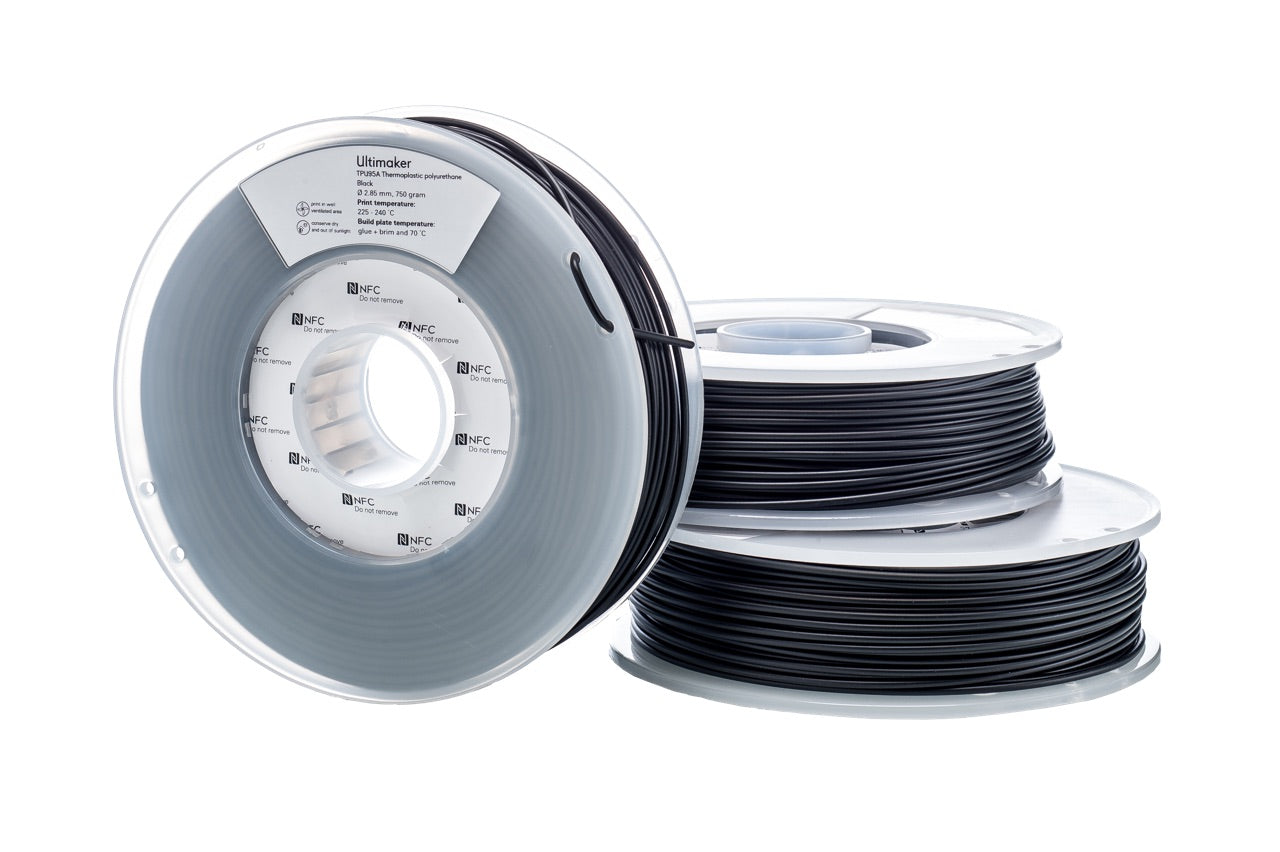

UltiMaker TPU 95A is a premium thermoplastic polyurethane (TPU) filament designed for exceptional flexibility and durability. Ideal for applications requiring the unique properties of both rubber and plastic, this filament is perfect for creating parts that need to withstand mechanical stress and chemical exposure.

Key Features

-

Flexibility and Durability: UltiMaker TPU 95A offers rubber-like flexibility combined with the strength of plastic, making it suitable for a wide range of applications, from prototypes to end-use parts.

-

Chemical Resistance: This filament is engineered to maintain its structural integrity and surface characteristics even in harsh chemical environments.

-

Ease of Printing: Unlike many flexible filaments, UltiMaker TPU 95A is optimized for easier and faster printing without compromising on layer bonding. This ensures a seamless 3D printing experience, reducing the likelihood of print failures.

-

Compatibility: UltiMaker TPU 95A is compatible with a variety of UltiMaker printers, including the S series, and 2+ series. It can be used with AA print cores for optimal results.

Applications

-

Prototyping: Test your designs with the same material properties as the final product, ensuring accurate performance evaluations.

-

End-Use Parts: Create durable, flexible components for various industries, including automotive, healthcare, and consumer goods.

-

Custom Designs: Utilize the versatile properties of TPU 95A to conform to existing part geometries or develop standalone components.

Why Choose TPU 95A?

UltiMaker TPU 95A stands out in the market due to its superior printability and performance. Whether you're a professional engineer or a hobbyist, this filament offers the reliability and quality you need for your 3D printing projects. Its exceptional wear and tear resistance, combined with rubber-like flexibility, make it an indispensable material for innovative and functional designs.