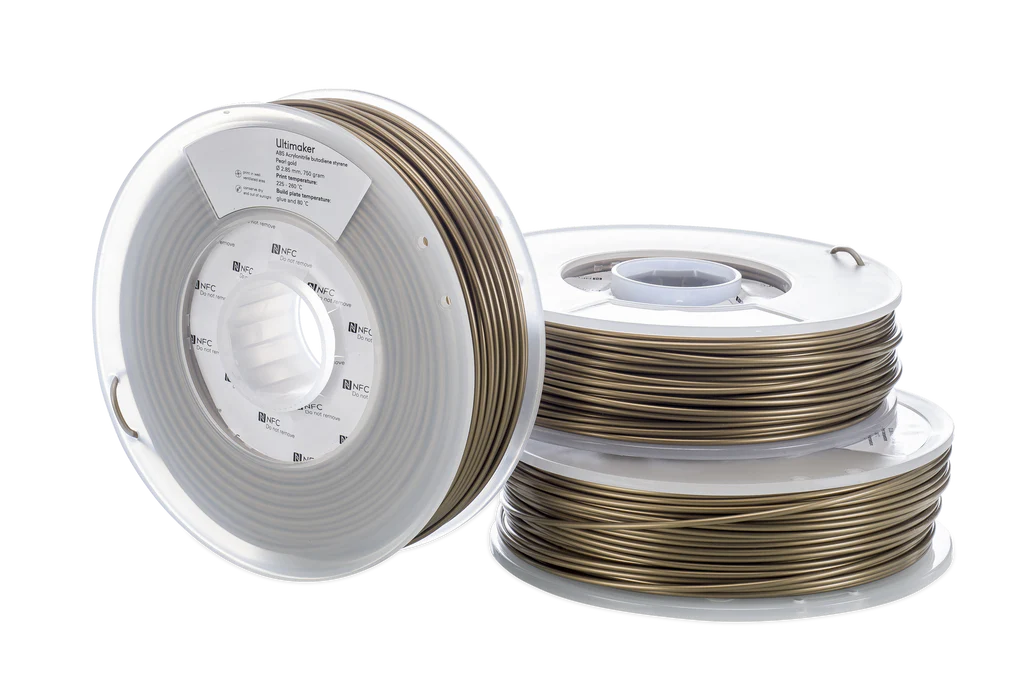

UltiMaker ABS (acrylonitrile butadiene styrene) is specifically formulated to minimize warping and ensure consistent interlayer adhesion. This makes it an excellent choice for creating functional prototypes and complex end-use parts that require durability and precision.

UltiMaker ABS is a reliable 3D printing filament that meets the diverse design requirements of engineers, hobbyists, and home users alike. Its minimized warping, consistent interlayer adhesion, and high-temperature resistance make it an ideal choice for functional prototypes and complex end-use parts. Whether you're working on simple prototypes or intricate components, UltiMaker ABS delivers the performance and reliability you need for your 3D printing projects.

Key Features

-

Minimized Warping: UltiMaker ABS is designed to reduce warping, ensuring that your 3D-printed parts maintain their shape and integrity throughout the printing process.

-

Consistent Interlayer Adhesion: This filament provides excellent interlayer adhesion, especially when printing with an enclosed front, resulting in strong and reliable parts.

-

High-Temperature Resistance: UltiMaker ABS can withstand temperatures of up to 85°C, making it suitable for applications that require heat resistance.

-

Aesthetic Detail: Achieve aesthetic detail that rivals injection molded parts, giving your 3D printed models a professional and polished appearance.

-

Dual Extrusion: UltiMaker ABS is available in a choice of 10 colours and can be used with Breakaway support material, providing versatility in your designs.

Why Choose ABS

-

Good Interlayer Adhesion: Ensures strong and reliable parts, especially when using an enclosed front during printing.

-

Temperature Resistance: Withstands temperatures of up to 85°C, making it suitable for heat-resistant applications.

-

Aesthetic Quality: Achieve high-quality aesthetic details that are comparable to injection molded parts.

-

Versatility: Dual extrusion with a choice of 10 ABS colours or Breakaway support material, allowing for creative and complex designs.

Applications

-

Functional Prototyping: Create durable and high-performance prototypes that can withstand rigorous testing and real-world conditions.

-

Complex End-Use Parts: Manufacture intricate and reliable end-use parts for various industries, including automotive, aerospace, and consumer goods.

-

Heat-Resistant Applications: Develop parts that require resistance to high temperatures, ensuring they maintain their integrity and performance.