Formlabs

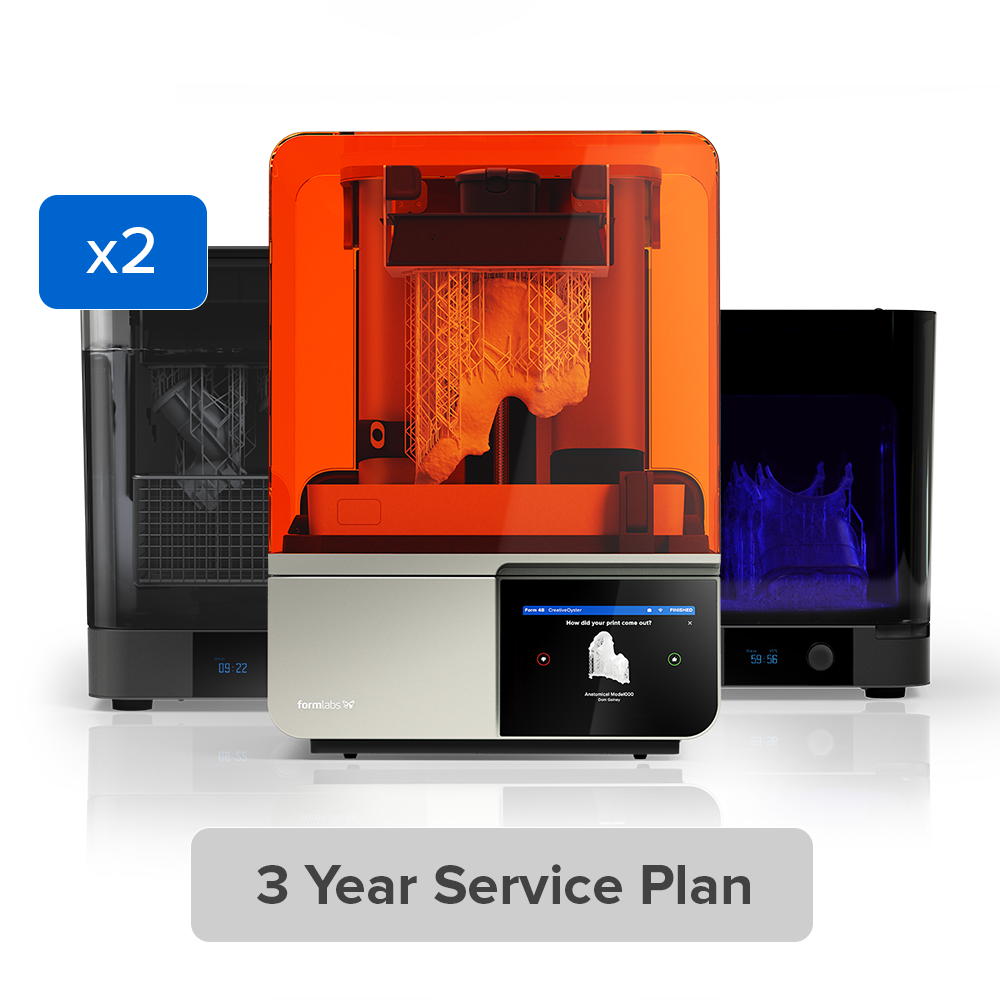

Form 4 Premium Package

The Formlabs Form 4 Premium Package includes everything you need to maximize productivity with multiple accessories and faster curing to ensure efficiency across your workflow. Featuring the next generation of Formlabs' proven SLA technology, the Form 4 delivers unmatched speed and accuracy without compromising on detail or material performance.

What's Included in the Form 4 Premium Package?

- Form 4 3D Printer

- 2x Form 4 Build Platform Flex

- Form 4 Resin Tank

- 2x Form Wash V2

- Form Cure V2

- Form 4 Finish Kit

- Form 4 Mixer

- Solvent Pump

- 3 Years Pro Service Plan

- Open Material Mode

- Finishing Tools

Why Choose the Formlabs Form 4?

- Unrivaled Speed - Print up to 5x faster than previous models with lightning-fast layer curing.

- Exceptional Accuracy - Industry-leading resolution ensures smooth surfaces and intricate details.

- Wide Material Compatibility - Supports a large library of resins, from standard to advanced engineering and biocompatible materials.

- User-Friendly Workflow - Intuitive software and automated post-processing simplify every step.

- Reliable & Scalable - Engineered for repeatable results, whether you're prototyping, manufacturing, or creating functional parts.

Ideal Applications:

Engineering & Manufacturing

Jewelry & Custom Design

Education & Research

Upgrade your 3D printing workflow with the Form 4 Premium Package today!

Tech Specs

| Category | Details |

|---|---|

| Technology | Masked Stereolithography (MSLA) |

| Printer Engine | Low Force Display® (LFD) |

| Key Components | Backlight Unit, LPU 4, Release Texture, Flexible Film Resin Tank, Intelligent Control Systems, High-Speed Automatic Resin Handling |

| Light Source | 60 uniform-wavelength LEDs with plano-convex lens array and integrated air cooling 405 nm optical wavelength 16 mW/cm2 optical power intensity 50 µm pixel size |

| Max Print Speed | 100 mm/hour (3.9 in/hour) |

| Typical Print Speed2 | 40 mm/hour (1.6 in/hour) Range: 16-50 mm/hour (0.6-2.0 in/hour), depending on material |

| Dimensional Tolerances3 | 1-30 mm: ±0.15% (min ±0.02 mm) 31-80 mm: ±0.2% (min ±0.06 mm) 81-150 mm: ±0.3% (min ±0.15 mm) |

| Surface Accuracy4 | 99.7% of surfaces within 100 µm of CAD 95% within 50 µm 69% within 25 µm (Precision Model Resin) |

| Reliability | 98.7% print success rate (independent lab tested) Learn More |

| Materials |

23+ Formlabs resins or 3rd party materials using Open Material Mode. |

| Biocompatible Materials | No (Available on Form 4B) |

| Build Volume (W x D x H)5 | 20 x 12.5 x 21 cm 7.9 x 4.9 x 8.3 in 5.25 L |

| Build Area | 250 cm2 / 38.8 in2 |

| Maximum Part Length6 | 27.3 cm / 10.7 in |

| XY Resolution7 | 50 µm (with anti-aliasing for subpixel resolution) |

| Layer Thickness8 | 25-200 µm (0.001-0.008 in) |

| Resin Cartridge | 1 next-gen cartridge 5-10x faster filling, 63% less waste, 30% less shelf space |

| Resin Heating | High-speed conduction with infrared temperature sensing |

| Operating Temperature | Auto-heats resin to 25-45°C (77-113°F) |

| Force Sensing | Z-Axis Force Sensor (auto-optimizes quality/speed) |

| Supports | Auto-generated, light-touch removal |

| Printer Dimensions (W x D x H) | 39.8 x 36.7 x 55.4 cm 15.7 x 14.5 x 21.9 in |

| Minimum Access Dimensions | 40.7 x 47.8 x 84.4 cm 16.0 x 18.8 x 33.2 in |

| Weight | 18.3 kg / 40.4 lb |

| Operating Environment | 18-28°C / 64-82°F |

| Power Requirements | 100-240 VAC, 4.8 A, 50/60 Hz, 480 W |

| Connectivity | Wi-Fi (2.4 & 5 GHz), Ethernet (1000 Mbit), USB-C 2.0 |

| Printer Control | 7" touchscreen (1280 x 800), multi-language |

| Alerts | On-screen, SMS/email via Dashboard, built-in speaker |

| Sensors | 6 upgraded sensors: - Infrared resin heating - Ultrasonic resin level - Z-axis force sensor - Resin cartridge load cell - Printer leveling sensor - Integrated camera |

| Camera | 5MP (2592 x 1944) for remote monitoring, timelapses, print history |

| Software | PreForm, Dashboard, Fleet Control |

| System Requirements | Windows 7+ (64-bit), macOS 10.15+ OpenGL 2.1, C++ runtime (Windows), 4 GB RAM (8 GB recommended) |

| Supported File Types |

Input: STL, OBJ, 3MF |

| PreForm Print Setup Features | One-Click Print Adaptive layer thickness for faster printing with fine details Remote Print Auto-orient for optimal print position Auto-mesh repair Auto-generation of supports Advanced tools for manually editing supports Rotate, scale, duplicate, and mirror Layer slicer for path inspection Custom print settings Available in multiple languages |

| Dashboard Printer Management Features | Manage prints and printers via the cloud Track resin and tank usage over time SMS and email alerts Create enterprise group accounts with admins to more easily share printers and control access |

| Resin Tank Lifetime | 75,000+ layers with any Formlabs material |

| LPU Lifetime | 600,000-1,900,000 layers depending on material and layer height |

1 Using Fast Model Resin and 200 µm layer height on the Form 4 Series. Based on actual print times from a collection of test parts covering common engineering, product design, manufacturing, and dental applications. Using Draft v2 Resin and 200 µm layer height on the Form 3 Series. Based on the 75th percentile actual print speed from reported prints in 2023.

2 Average across all materials printed at 100 µm layer height, weighted by material popularity. Print speed will vary depending on the material, layer height, and part geometry. The range is based on the materials with the slowest median print speed and highest median print speed.

3 Using Grey Resin V5 and 100 µm layer height, post-cured for 5 minutes at room temperature. One test model with various feature sizes 3D printed on three different printers.

4 Using 50 µm layer height. Tested using a full arch restorative model with dies, four models per print job, printed on three different printers, and post-processed according to the recommended settings.

5 If you are printing a job that is taller than 19.0 cm (7.5 in) on Form 4/B, taller than 30.5 cm (12 in)in) on Form 4L/4BL, or taller than 18.5 cm (7.2in) on Form 3/B/+, you have to remove the resin tank while removing your print. PreForm will warn users when their job is above these limits.

6 Assuming a part printed on supports that resembles a rectangular prism with 12.5 cm depth and 1 cm height.

7 XY resolution describes how precisely the printer can cure the resin in the XY (horizontal) plane. It corresponds to the pixel size of the Light Processing Unit 4 and Light Processing Unit 4L.

8 Layer thickness availability varies by material. View our materials compatibility table to confirm availability.

9 Languages beyond English will come in future firmware releases on the Form 4 Series.

10 The exact lifetime of an individual resin tank depends on layers printed, physical wear, and accidental damage.

11 Using 100 µm layer height. The exact lifetime of an individual LPU depends on total light energy passed through the module, which depends on number of layers printed, material, and layer height, as well as accidental damage. When replacement is necessary, anyone can easily and quickly replace the LPU 4 or LPU 4L at a low cost.